Be it a packet of sugar, table, and pencil or hairclips, laptops, and switches, we see manufactured products everywhere. We are familiar with the fact that these daily use or commercial products are assembled with the help of life-size machinery. However, have you ever wondered how those manufacturing machinery are made in the first place? Tool and die makers are such professionals who through their creativity, skills, and knowledge mould the raw materials into products that are used to build humongous machines. Had there been no tool an die making experts, shaping plastic/ metals, creating unique tools and assembling dies to stamp out the parts would not have been possible. Through this blog, we will shed light on various aspects pertaining to one of the creative career options including the career prospects and skills required.

This Blog Includes:

General Overview

Also called highly-skilled Machinists, Tool and Die Makers are responsible for producing tools, die and other parts of machines that are used further to assemble certain products. Having a broad knowledge of machine operations and principles of Mechanical Engineering, the professionals are experts in carrying out work with precision. They also have a high aptitude for mathematics and the ability to read blueprints. Moreover, these professionals also fabricate jigs, fixtures, and devices that hold the metal together while it is drilled, bored or stamped. Tool and Die making also involves the usage of CAD/CAM software to get the required tool or die.

Skills Required for Tool and Die Making

Precision, patience, and creative thinking are some of the skills that an individual, who wants to build a career in this field requires. Apart from this, here are a few other competencies that one must possess in order to proceed in the field of tool and die making:

- Mechanical Skills

- Analytical Skills

- Manual Dexterity

- Physical Stamina

- Maths And Computer Skills

- Technical Skills

- Problem-solving Skills

- High Concentration Levels

Educational Qualifications

The job of a tool and die maker is completely dependent upon the amount of work experience an aspirant has. Therefore, pursuing a career in tool and die making is not the cup of tea for everyone. Further, with the advent of new technology and the need to perform tool and die making process with precision, it has become important for the aspirants to learn newer skills and be at par with the latest changes. Given below are some of the most general educational qualifications that an aspirant needs to fulfill.

- Generally, the individuals who are enticed with this field need to pass their higher secondary level of studies with MPC subjects.

- For those who want to work as machinists, a high school diploma or equivalent will suffice.

- Subsequently, they need to get a 4 to a 5-year academic degree in engineering or technology in Mechanical Engineering from one of the best mechanical engineering colleges in the world. For example, at the undergraduate level, the students can choose to pursue either a BTech or a BE Mechanical Engineering. Whereas, at the postgraduate level, the students can choose to opt for either an MTech or MS in Mechanical Engineering.

- Upon completing the education, the candidate must obtain training through apprenticeship programs in either of the fields of tool and die making, such as Tool Engineering, Blueprint Reading, Tool Programming and so on.

Note: The candidates having sound knowledge of Physics and Mathematics, and hold a strong educational record are preferred by the employers for apprenticeship or internships.

Tool and Die Making: Career Prospects

A career in tool and die making entails an enormous amount of career opportunities for the aspirants. As more and more industries are setting up and newer technologies are coming into existence, the demand for professionals in all the sectors of the economy has seen a steep rise. Enlisted are some of the work profiles you can work after pursuing a course in this field:

- University Professor

- Tool Room Manager/Assistant

- Gear Machinists

- Maintenance Machinists

- Automotive Machinists

- Metal Gauge Makers

- Tool Makers

- Die Makers

- Precision Machinists

- Manual Lethal Machinists

- Jig Bore Tool Makers

- CNC Machinists

- Metal Die Finisher

Hopefully, you are now aware of the information pertaining to how to kickstart a career in tool and die making. If you are confused about what to study after 12th then, a good educational counselling goes a long way! Take the guidance from experts at Leverage Edu who will help you choose the course which best suits your interests and skills after gauging through your profile through a psychometric test!

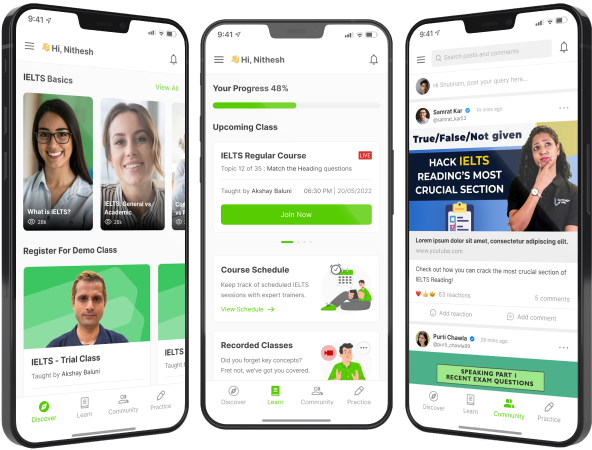

One app for all your study abroad needs

One app for all your study abroad needs

45,000+ students realised their study abroad dream with us. Take the first step today.

45,000+ students realised their study abroad dream with us. Take the first step today.