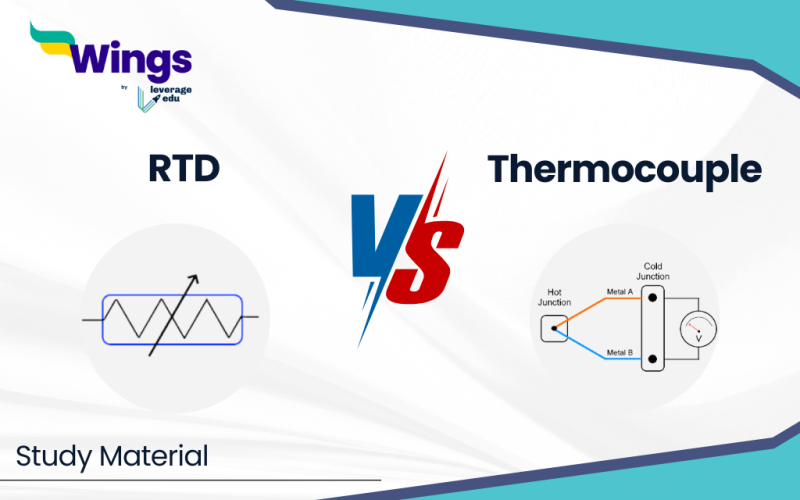

The main difference between RTD and Thermocouples lies primarily in their principles of operation, temperature ranges, accuracy, response times, cost, and interfacing requirements. RTD stands for Resistance Temperature Detectors and Thermocouples are both types of temperature sensors, but they work in different ways. RTDs measure temperature based on the change in electrical resistance of a metal wire as temperature changes. On the other hand, Thermocouples use the Seebeck effect, which is when two different metals come together and create a voltage based on the temperature difference between the two metals and a reference point.

While they are durable and can handle higher temperatures, they are usually less accurate than RTDs. The choice between RTD and thermocouples depends on factors such as temperature range, accuracy requirements, and environmental conditions. Keep reading to get more information about the difference between RTD and Thermocouples.

Table of Contents [show]

What is RTD?

A resistance Temperature Detector is a kind of temperature monitor that is used to correctly measure temperature in many fields. RTD operates on the principle that the electrical resistance of certain materials changes predicated as the temperature changes. As the temperature increases, the resistance of the element also increases. Common materials used for RTDs include platinum, copper, and nickel.

RTDs are known for their accuracy, stability, and repeatability, making them suitable for applications where precise temperature measurements are required, such as industrial processes, environmental monitoring, and laboratories.

What is a Thermocouple?

A temperature sensor called a thermocouple is made up of two different metals that are connected at one end. A voltage equal to the difference in temperature between the two ends is made when there is a temperature change. This process is known as the Seebeck effect. Thermocouples are widely used for temperature measurement in various industrial, scientific, and commercial applications due to their simplicity, durability, and wide temperature range capabilities.

There are different types of thermocouple combinations available, each with its temperature range, accuracy, and characteristics. Type K (chrome/alumel), Type J (iron/constantan), and Type T (copper/constantan) are some of the most common. Thermocouples are used for many things, like temperature monitoring in industrial processes, HVAC systems, food processing, automotive, aerospace, and more.

Also Read: Difference Between GHz and MHz

What is the Difference Between RTD and Thermocouple?

Here’s the difference between RTDs (Resistance Temperature Detectors) and thermocouples are mentioned below.

| Particulars | RTD (Resistance Temperature Detector) | Thermocouple |

| Principle | Utilizes the change in electrical resistance of a material with temperature. | Based on the Seebeck effect, which generates a voltage when two dissimilar metals are joined at the sensing end. |

| Sensing Element Material | Typically platinum, nickel, or copper. | Consists of two different conductive metals joined together (e.g., chrome/alum, iron/constantan). |

| Temperature Range | Generally suitable for moderate to high-temperature ranges, from -200°C to 850°C or higher, depending on the material. | Wide temperature range capability, from cryogenic levels to several thousand degrees Celsius. |

| Accuracy | Higher accuracy compared to thermocouples. | Generally lower accuracy compared to RTDs. |

| Stability | Offers better long-term stability and repeatability. | Stability may vary and can be affected by factors like material purity and environmental conditions. |

| Response Time | Slower response time compared to thermocouples. | Typically faster response time, making them suitable for dynamic temperature measurements. |

| Cost | Generally more expensive compared to thermocouples. | Usually less expensive than RTDs. |

| Interchangeability | Less interchangeable due to different resistance vs. temperature characteristics. | More interchangeable, as they are standardized based on type (e.g., Type K, Type J). |

| Environmental Sensitivity | More sensitive to vibrations and mechanical shocks. | Less sensitive to mechanical stress and vibrations. |

| Applications | Commonly used in applications requiring precise and stable temperature measurements, such as laboratories, industrial processes, and environmental monitoring. | Widely used in various industries for temperature measurement, including industrial processes, HVAC systems, automotive, aerospace, and more, especially in harsh environments. |

Difference Between RTD and Thermocouple Formulas

RTD Formula

The primary formula used for calculating temperature in an RTD is the “Callendar-Van Dusen Equation. This equation is related to the resistance of the RTD element (R(T)) at a specific temperature (T) to its resistance at 0°C (R0) through a series of coefficients (A, B, and C).

| R(T) = R0 (1 + A × T + B × T² – 100 × C × T³ + D × T⁴) |

Where:

R(T) = Resistance of the RTD at temperature T (°C)

R0 = Resistance of the RTD at 0°C (°C)

A, B, C, and D = Material-specific constants defined by the RTD standard (often IEC 751)

#Important Note: The coefficients (A, B, C, and D) vary depending on the RTD element material (e.g., Platinum = Pt100).

Thermocouple Formula

There isn’t a single method that can be used to figure out temperature using thermocouples. This is because the voltage output of a thermocouple depends on the type of thermocouple (the metals that are used together) and the reference temperature (the temperature where the thermocouple wires are connected).

- Measure the voltage (EMF) generated by the thermocouple.

- Use reference tables or polynomial equations specific to the thermocouple type.

- These tables or equations correlate the measured voltage with the temperature difference between the measurement junction and the reference junction.

Application of Difference Between RTD and Thermocouple in Real-Life

Both RTDst and Thermocouples, play important roles in our daily lives by providing accurate temperature measurements in various applications.

- Precision Industries

- Semiconductor Manufacturing

- Chemical Pharmaceutical Industries

- Calibration labs

- Food and Beverage Industry

- Food processing

- Oven and refrigerators

- Power Generation

- Chemical Processing Plants

Also Read: What is the Difference Between Device and Machine? Complete Details

FAQ’s

Thermocouples are generally more cost-effective than RTD sensors.

The resistance to the flow of electricity goes up as the temperature of a metal goes up.

The resistance to the flow of electricity goes up as the temperature of a metal goes up.

RELATED BLOGS

This was all about the “Difference between RTD and Thermocouple”. For more such informative blogs, check out our Study Material Section, you can learn more about us by visiting our Indian exams page

One app for all your study abroad needs

One app for all your study abroad needs

45,000+ students trusted us with their dreams. Take the first step today!

45,000+ students trusted us with their dreams. Take the first step today!